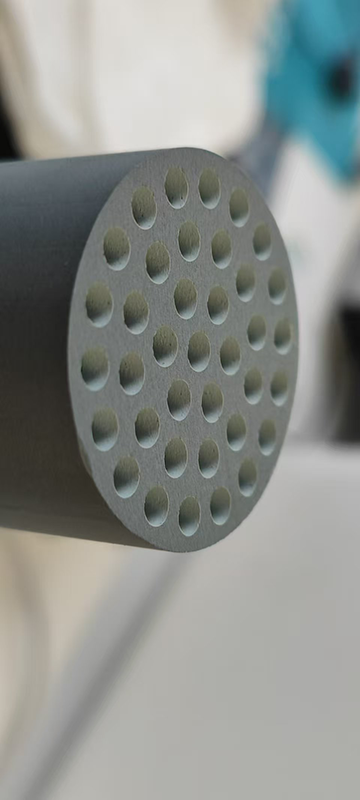

Recrystallized Silicon Carbide Tubular Membrane

Recrystallized silicon carbide inorganic membrane is a high-tech silicon carbide material formed by mixing high-purity silicon carbide coarse powder and high-activity silicon carbide micropowder, and vacuum sintering at a high temperature of 2450℃ to make it recrystallized. Due to its high material purity (SIC≥99.5%) and no intermediate binding phase, it has excellent high-temperature mechanical properties and is currently the membrane material with the best hydrophilicity and anti-pollution ability.

Details

Recrystallized silicon carbide is fired by the process.During the sintering process,the sintering neck between the silicon carbide aggregates is a phase change process from solid to gaseous to solid.The porosity is as high as 45%,and the formed filtration channel has strong connectivity.In addition,the natural hydrophilicity of silicon carbide materials(contact angle is only 0.3°),the pure water flux is as high as 3200LMH,and it is hydrophilic and oleophobic.

Main application areas of ceramic membranes

1.Fermentation broth clarification technology:filtration of fermentation broth of animal and plant extracts,enzyme reactions(acrylamide,p-hydroxyphenylglycine),organic acids(lysine,L-lactic acid,citric acid,nucleotides),antibiotics(penicillin,cephalosporin,erythromycin,colistin sulfate,gibberellin, vancomycin);

2.Extraction and purification of effective ingredients of traditional Chinese medicine;

3.Clarification and filtration of oral liquid;

4.Sterilization and impurity removal filtration of brewed products such as soy sauce and vinegar;

5.Clarification and filtration of fruit juice, beverages, and alcoholic beverages;

6.Sterilization and concentration of milk;

7.Separation and refining of fermentation products;

8.Treatment of oil-containing emulsion wastewater: oilfield reinjection water, cold rolling emulsion wastewater, and metal cleaning liquid recovery;

Note

Prevent bumps: When installing the membrane core, handle it with care, use a soft hammer and plastic tools, and do not throw, drop or smash it.

Prevent vibration: The membrane core must be transported with styrofoam packaging materials, and direct transportation without packaging materials is prohibited. After the membrane core is loaded into the membrane barrel, it must be kept in a vertical state for transportation and filtration operations.

Prevent freezing: After the membrane core is loaded into the equipment and contacts the liquid, the equipment must be kept at a temperature above 0 degrees Celsius to prevent freezing. If the temperature of the equipment cannot be guaranteed to be above the freezing point when it is shut down, antifreeze such as glycerol solution, ethylene glycol solution, etc. must be injected to prevent the membrane core from freezing and cracking.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)