Application of Silicon Carbide Combined with Silicon Nitride Materials in the Lithium Battery Industry Chain

2026-02-04 09:51

Silicon Carbide Combined with Silicon Nitride Materials: A New Performance Upgrade Engine for the Lithium Battery Industry Chain

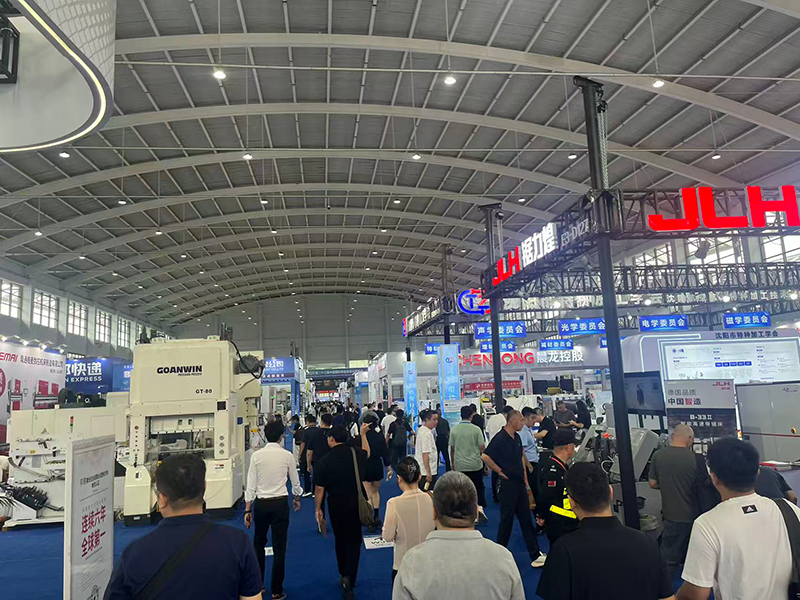

Today, Shenyang Starlight Advanced Ceramics Co., Ltd. successfully held a case analysis seminar on the application of silicon carbide combined with silicon nitride materials in the lithium battery industry chain, bringing together industry experts and enterprise representatives to jointly explore the innovation path of advanced ceramic materials to empower the new energy industry. As an enterprise focusing on the research and development and production of silicon carbide materials, Shenyang Starlight has provided solid practical support for this industry exchange with years of technology accumulation.

Silicon carbide combined with silicon nitride materials has become a key upgrade material in the lithium battery industry chain with its excellent performance. The material forms a dense structure through high-temperature reaction, which combines the high hardness of silicon carbide with the strong toughness of silicon nitride, with a hardness of 9 on the Mohs scale, which can withstand a high temperature of 1650°C, excellent thermal conductivity and a small coefficient of thermal expansion, which can effectively resist chemical attack and thermal shock. These characteristics make it irreplaceable value in the core link of lithium batteries: in the synthesis of cathode materials, the corrosion resistance of the cassette bowl made of this material avoids the erosion of raw materials such as lithium salts, and the uniform thermal conductivity improves the crystallinity of ternary materials, significantly improves the product qualification rate, and extends the service life by more than 50%, reducing production energy consumption; In power module packaging, silicon nitride combined with silicon carbide substrate has better thermal conductivity and insulation than traditional materials, and with crimping technology, it can increase module reliability by 10 times, form a synergistic effect with lithium batteries, and help increase the efficiency of energy storage systems by 25%.

At the seminar, a number of application cases sparked heated discussions. A battery company uses the crucible of this material to carry out the anode material coating carbonization process, achieving stable production in a high temperature environment of 1800°C, and improving the volatile content control accuracy by 30%; In the energy storage power station project, the thermal management components made of this material successfully solve the problem of high-temperature operation of lithium batteries, extending the cycle life of the system to more than 10 years. Experts pointed out that with the development of solid-state battery technology, the application of this material in new scenarios such as electrolyte support and insulation protection will be further expanded, promoting the upgrading of the industrial chain to high safety and long life.

The relevant person in charge of Shenyang Starlight Advanced Ceramics Co., Ltd. said that he will take this seminar as an opportunity to continue to deepen technical collaboration with upstream and downstream enterprises, focus on high-purity powder preparation and low-cost process innovation, so that silicon carbide combined with silicon nitride materials can play a greater value in the lithium battery industry chain and inject strong impetus into the high-quality development of the new energy industry.

Get the latest price? We'll respond as soon as possible(within 12 hours)