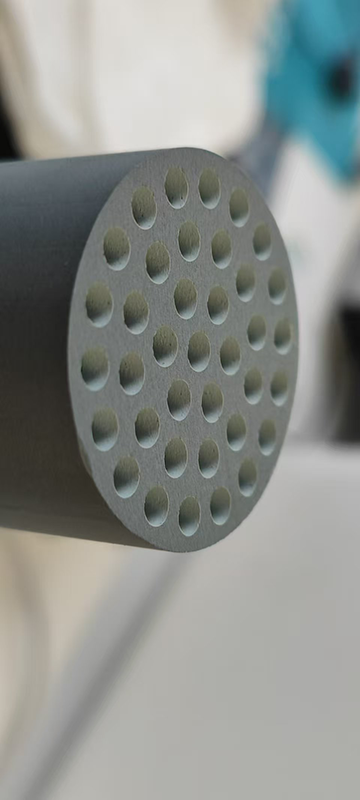

Recrystallized silicon carbide pillar membrane

1.The silicon carbide membrane is fired by a recrystallization process with a sintering temperature of 2400℃.

2.The opening rate is as high as over 45%, and the formed filtration channel has strong connectivity.

3.Coupled with the natural hydrophilicity of silicon carbide material (contact angle of only 0.3°),.

4.The pure water flux is as high as 3200LMH, which is hydrophilic and oleophobic.

Details

Recrystallized Silicon Carbide (RSiC) Tubular Membranes

Key Features and Industrial Applications

Recrystallized silicon carbide tubular membranes, a breakthrough in advanced ceramic materials, have emerged as transformative solutions across industries due to their unique structural and functional properties.

Core Characteristics

Exceptional Chemical Stability: Recrystallized silicon carbide membranes maintain structural integrity in extreme pH environments (pH 1–14) and resist corrosion from acids, alkalis, and organic solvents, enabling prolonged operation in aggressive media like chemical processing wastewater.

Mechanical Robustness: With Vickers hardness exceeding 25 GPa, these membranes demonstrate superior resistance to abrasion and high-pressure conditions (up to 10 MPa),ideal for filtration in mining slurries and catalytic reaction systems.

Thermal Endurance:Operating stably at temperatures up to 1,600°C,Recrystallized silicon carbide excels in high-temperature applications such as molten metal filtration and flue gas treatment,outperforming polymer and alumina counterparts.

High Permeability:The unique recrystallization process creates interconnected pores with 45% open porosity,achieving pure water flux rates of 3,200 LMH—3–5×higher than traditional ceramic membranes.

Anti-Fouling Performance: Surface negative charges across wide pH ranges (isoelectric point ~pH 3) repel organic contaminants, while ozone-resistant surfaces allow intensive oxidative cleaning, reducing downtime by 40%.

Industrial Applications

Water & Wastewater Treatment: Municipal plants utilize Recrystallized silicon carbide membranes for oil-water separation (99.8% efficiency) and heavy metal removal, leveraging their hydrophilicity (contact angle 0.3°) and acid resistance .

Chemical & Pharmaceutical: Pharmaceutical companies employ these membranes in continuous API purification and solvent recovery, capitalizing on their solvent stability and steam-sterilizable surfaces .

Energy & Metallurgy: In coal-to-liquids processes, Recrystallized silicon carbide filters remove catalyst fines at 800°C, while their thermal shock resistance (ΔT > 500°C/min) benefits nuclear reactor coolant systems .

Future Outlook

Ongoing R&D focuses on scaling production of 1.2m-length monolithic membranes and AI-optimized pore architectures. Collaborations between academia and industry aim to reduce manufacturing costs by 30% through modified sintering techniques .

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)