The construction ceremony of the silicon carbide-based semiconductor core components factory began

Shenyang Starlight Advanced Ceramics Embarks on Semiconductor Ecosystem Expansion with New Production Facilities

Shenyang Starlight Advanced Ceramics Co., Ltd., China's pioneering advanced silicon carbide kiln furniture manufacturer established in 1995 through a landmark Sino-German joint venture with Fine Technical Ceramics GmbH, today announced a strategic leap into semiconductor supply chain integration. The company commenced construction of its semiconductor core component production facility and CVD (Chemical Vapor Deposition) workshop on June 10, 2025, marking a transformative phase in its three-decade journey of technological innovation.

Strategic Expansion Overview

This $350 million investment project reinforces Shenyang Starlight's commitment to vertical integration in semiconductor manufacturing:

Core Component Facility: Dedicated to mass-producing ultra-high-purity silicon carbide parts for wafer handling, thermal management, and process chambers.

CVD Workshop: Specializing in advanced silicon carbide coatings for semiconductor equipment, including plasma-resistant and anti-corrosion layers.

Integrated R&D Center: Housing cutting-edge materials analysis laboratories and process simulation systems.

Technical Capabilities

The new facilities will leverage Shenyang Starlight's legacy strengths:

Material Expertise: 30 years of RSiC (Recrystallized silicon carbide) and NSiC (Nitride-Bonded silicon carbide) production experience

Quality Heritage: China's first ISO 9001-certified silicon carbide kiln manufacturer (2002)

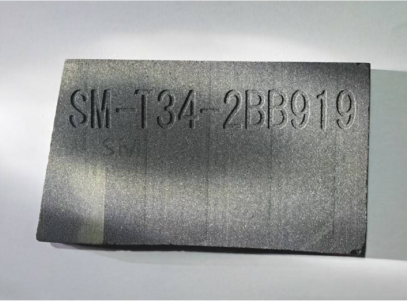

Precision Engineering: Sub-0.01mm machining accuracy proven in semiconductor-grade components

Global Recognition: 35% export share across 20+ countries (per 2024 customs data)

Facility Specifications

Semiconductor Component Plant

Cleanroom Standards: ISO Class 5-7 environments

Production Capacity: 50,000+ precision parts annually

Key Products:

12-inch wafer carriers (450mm OD)

CVD/CVI process tubes

Edge ring components for etching systems

CVD Coating Workshop

Deposition Technologies: PECVD, LPCVD, and ALD capabilities

Coating Performance:

≤0.05μm surface roughness

99.999% purity coatings

10,000+ cycle durability

Industry Impact

This expansion addresses critical supply chain needs:

Localization: Reducing reliance on imported semiconductor components by 40%

Technical Breakthroughs: Developing proprietary high-entropy silicon carbide coatings

Sustainability: Implementing closed-loop material recycling systems

R&D Collaboration

The project builds on existing partnerships with:

Tsinghua University: Joint development of AI-driven process optimization systems

Northeastern University: Advanced thermal stress modeling for large-format components

CAS Institutes: Next-generation ceramic matrix composites

Project Timeline

June 2025: Foundation completion

Q4 2025: Equipment installation

Q2 2026: Pilot production

2027: Full capacity operation

Leadership Perspective

"This expansion represents our evolution from kiln specialist to semiconductor solutions architect," stated Mr. Liu Changchun, Chairman. "By integrating CVD capabilities with precision manufacturing, we're positioned to deliver complete subsystem solutions for 3nm node fabs."

Market Positioning

The initiative aligns with China's semiconductor self-sufficiency goals, targeting:

25% market share in domestic silicon carbide components by 2028

50% reduction in lead times for advanced silicon carbide coatings

30% cost advantage over imported alternatives

Sustainability Commitments

Energy Efficiency: 40% reduced power consumption via waste heat recovery

Emission Control: 99.9% particulate filtration in CVD processes

Material Utilization: 95%+ yield rate through AI-optimized machining

Get the latest price? We'll respond as soon as possible(within 12 hours)