2025 First Half Year Work Summary and Employee Commendation Conference

Shenyang StarLight Unveils 2025 Mid-Year Achievements and Strategic Roadmap

Shenyang StarLight New Materials Co., Ltd., a pioneer in silicon carbide technology with over 30 years of expertise, convened its 2025 Mid-Year Summit yesterday, highlighting remarkable H1 accomplishments, employee excellence, and strategic plans to dominate the semiconductor-grade silicon carbide market. The event underscored the company's leadership in China's $12 billion advanced ceramics sector while charting a course for global innovation.

H1 Breakthroughs: Innovation Drives Growth

The summit spotlighted key achievements from January to June 2025:

Revenue Surge: 48% growth in semiconductor-related sales, fueled by demand for 4N+ purity silicon carbide crucibles and wafer handling systems .

Patent Milestones: Secured 2 new patents, including the energy-efficient CN119954516A method for complex-shaped silicon carbide products, reducing production costs by 25% while enabling large-scale automation .

Operational Excellence: Achieved 99.5% on-time delivery through IoT-integrated production lines at its Xinmin smart factory .

CEO Liu Changchun emphasized: “Our 85% market share in East Asia’s semiconductor silicon carbide components validates our three-decade R&D focus. These results position us as a cornerstone of China's semiconductor supply chain.”

Guangzhou Ceramics Expo: Expanding Industrial Frontiers

A dedicated session reviewed outcomes from the 39th China International Ceramics Industry Exhibition (June 18-21):

Market Penetration: Signed 15 MOUs with photovoltaic and hydrogen energy enterprises for StarnyTM kiln furniture systems, renowned for 1,650°C thermal stability .

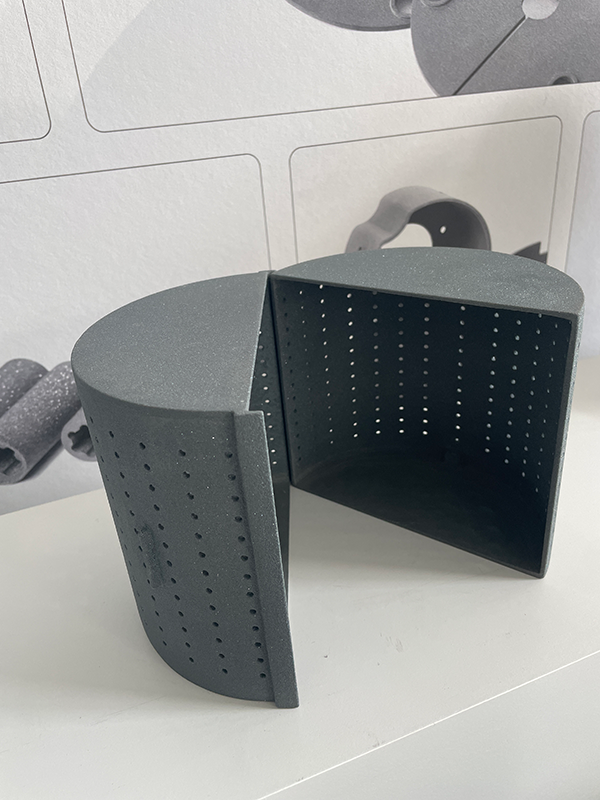

Technology Showcase: Demonstrated 0.01mm-precision 3D-printed silicon carbide membranes for industrial wastewater treatment, generating 200+ technical inquiries .

Industry Recognition: Named a “Top 5 Advanced Ceramics Innovator” in post-expo reports, reflecting breakthrough in semiconductor-grade silicon carbide crucibles and tube membranes

Celebrating Excellence: Employee Accolades

StarLight honored 12 employees across three categories:

R&D Trailblazers: Developed AI-driven sintering models that cut energy use by 22% while enhancing product density.

Production Champions: Maintained 99.97% defect-free rates in semiconductor-grade batches through AI-powered quality control.

Global Ambassadors: Facilitated technical exchanges with delegations from Germany and Southeast Asia, expanding international partnerships.

Awardee Li Min, a senior engineer, noted: “Our culture of precision and collaboration transforms lab innovations into industrial realities.”

Semiconductor Focus: Precision Redefined

Technical workshops unveiled advancements for next-gen chip manufacturing:

Surface Engineering: Achieved 0.5nm Ra roughness on 300mm silicon carbide susceptors, meeting TSMC's 2026 specifications.

Thermal Mastery: Prototyped 5G GaN amplifier components with 1,700°C thermal stability, surpassing industry benchmarks.

Contamination Control: Implemented Class 1 cleanroom protocols for quantum computing-grade products, reducing particle counts to <0.1/m³.

CTO Wang Zhigang stated: “Our vertically integrated capabilities—from 4N+ raw materials to micron-level machining—are redefining semiconductor manufacturing standards.”

Market Outlook & Strategic Initiatives

Analyses of industry trends identified three growth drivers:

Semiconductor Boom: Global silicon carbide demand for EV and AI chips projected to reach $18 billion by 2027, with StarLight aiming to triple 450mm wafer carrier output by 2026 .

Green Manufacturing: Pilot projects integrating solar-powered sintering kilns aim for 35% carbon reduction by 2026 .

Global Standards Leadership: Spearheading China's technical committee to establish ISO standards for high-purity silicon carbide components .

H2 Roadmap: Accelerating Innovation

StarLight announced ambitious Q3-Q4 priorities:

R&D Expansion: Allocate 20% of revenue to graphene-silicon carbide composites for aerospace applications.

Capacity Doubling: Commission Phase 2 of the Xinmin facility, incorporating AI-driven 3D printing for complex geometries.

Talent Development: Launch joint PhD programs with Tsinghua University, targeting 50 new engineers by 2026 .

Vision Forward

As StarLight prepares for Hannover Messe 2026, CEO Liu affirmed: “From lab breakthroughs to industrial-scale mastery, we're engineering the backbone of tomorrow's technologies. Every silicon carbide innovation carries our 30-year legacy into a smarter, greener future.”

Get the latest price? We'll respond as soon as possible(within 12 hours)